Seaweed plastic scales up

WA startup Uluu has unveiled the next step in its scale-up plans in the wake of a multimillion-dollar funding round.

Perth-based Uluu has outlined scale-up plans for its plastic alternative tech after securing $16 million in Series A funding.

The funding round, led by a German growth investor Burda Principal Investments (BPI), will support construction of a 10-tonne-per-year demonstration plant in Western Australia – a big step up from Uluu’s current 100-kilogram pilot facility.

According to Uluu, the new site will enable it to supply commercial volumes of its product to global partners across the fashion, cosmetics and automotive industries, and pave the way for large-scale production.

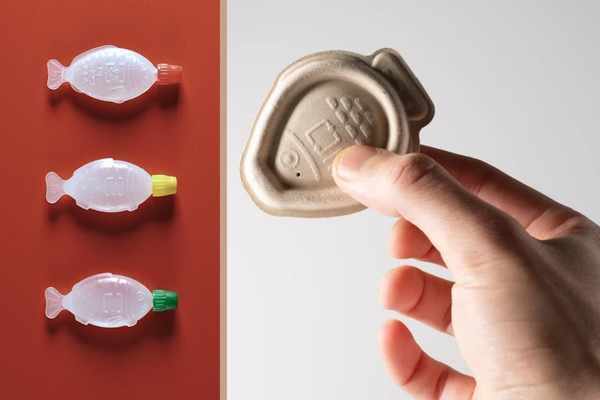

Uluu has previously teamed up with fashion brands Quiksilver and Papinelle on accessories such as wax surfboard combs and luxury pyjama buttons, and ultimately, the startup hopes its products will be used to make textiles that can replace polyester, a major contributor to global plastic waste.

The company was founded in 2021 by marine scientist Julia Reisser and former mergers & acquisitions lawyer Michael Kingsbury to develop a method to transform seaweed into a natural bioplastic.

The tech combines seaweed and fermentation in a process the startup likens to brewing beer, resulting in natural polymers called PHAs.

Uluu says its product looks and feels like conventional plastic but is reusable, recyclable, compostable and marine biodegradable, and can be processed using existing industrial equipment.

“The demonstration plant is a critical step in showing Uluu can scale to truly compete with and replace fossil plastics.”

Over the past year the startup has grown from 13 to 23 staff and strengthened its technical, operations and commercial teams. Plans are also underway for a commercial-scale facility capable of producing thousands of tonnes annually to serve major global markets, according to Uluu.

Uluu co-founder and co-CEO Michael Kingsbury said the new facility marked a turning point for the company.

“After four years’ work developing this technology, including two years’ running our pilot plant, we’re excited to take this next step and start delivering meaningful volumes of our materials to customers,” he said.

“The demonstration plant is a critical step in showing Uluu can scale to truly compete with and replace fossil plastics.”

The bigger picture

The news comes amid growing concern about the environmental toll of fossil-fuel-based plastics, which emit carbon throughout their lifecycle and can persist for centuries in landfills and oceans.

Each year, millions of tonnes of plastic waste enter marine ecosystems and break down into microplastics that contaminate food chains and harm wildlife. Today, less than 10% of plastic is recycled, according to researchers.

Uluu’s approach aims to replace those plastics entirely with materials made from renewable ocean resources. Its materials are produced from seaweed, a fast-growing, regenerative marine crop that requires no fertiliser, land, or freshwater.

“Seaweed grows quickly and gets everything it needs from the sun and the sea,” said co-founder and co-CEO Dr Julia Reisser.

“It locks away CO₂ and helps clean up pollutants from the ocean. By harnessing seaweed, Uluu is producing materials that have a positive, rather than negative, impact on the environment, while ending plastic pollution.”

Uluu estimates that its production process could sequester and avoid around five kilograms of CO₂ for every kilogram of material produced, compared to roughly three kilograms emitted by conventional plastics, and hopes its technology could one day help reduce global CO₂ emissions by two gigatonnes annually.

Seaweed’s moment

Uluu’s rise comes amid a wave of new startups and research ventures focused on ocean-based innovation, from biobased materials to burp-busting cattle feed and seaweed-derived foods.

FutureFeed and its licensees CH4 Global and Sea Forest are scaling cultivation of the red seaweed Asparagopsis, which has been shown to substantially cut methane emissions from cattle. Rumin8, based in Perth, is taking a laboratory approach, replicating the same active compounds without the need for seaweed farms.

PhycoHealth is producing food-grade products from farmed seaweed in NSW, while Sydney’s Coast 4C works globally to support regenerative seaweed farming and coastal livelihoods.

Uluu's Series A round, which was led by Burda Principal Investments (BPI), included backing from Main Sequence, Novel Investments, Startmate, Fairground, and Trinity Ventures.

“At BPI, we invest in companies driving transformative innovation with the potential to become a global category leader,” BPI CEO Christian Teichmann said.

“Having first invested in Uluu in 2023, we’re excited to further deepen our partnership as the company scales its pioneering technology.”

Uluu’s technology combines seaweed and fermentation to produce natural polymers called PHAs (polyhydroxyalkanoates), in a process the startup describes as similar to brewing beer. The method begins with seaweed, which absorbs carbon dioxide as it grows. During fermentation, microorganisms convert the seaweed’s sugars into PHAs, creating a versatile biopolymer that can be moulded, recycled, or composted. These polymers form the base for materials that, according to Uluu, look and feel like conventional plastics but biodegrade naturally in soil and seawater.

Related stories