Enzyme tech levels up

Australian biotech company Samsara Eco has cut the ribbon on its first commercial-scale plastic recycling plant in regional NSW.

A new $30 million commercial-scale enzyme-based recycling plant has been unveiled by Samsara Eco in Jerrabomberra near Canberra.

The facility represents the next step in the startup’s mission to turn mixed plastic waste into high-quality raw materials that can be infinitely recycled using enzyme-based tech.

These mixed plastics include nylon 6,6 and polyester, which the company says are suitable for reuse in sectors like fashion, packaging, and the automotive industry.

Currently, less than 1% of textiles are repurposed into new garments, Samsara Eco said, with the rest often ending up in landfill or incinerated.

Traditional systems struggle when it comes to processing mixed and contaminated plastics, according to the company, which hopes its enzyme tech will offer a potential new pathway.

"This is a true tipping point for circularity, shifting circular materials from early-stage innovation to mainstream reality"

Samsara Eco says its raw materials will not only be available to brands to incorporate into their product lines, but they can also re-enter the supply chain repeatedly.

“The opening of Jerrabomberra is a proud milestone for us and the broader circular economy,” Samsara Eco CEO and founder Paul Riley said.

“In just four years, we’ve scaled from bench research through to pilot, demonstration, and now our first plant. This is a true tipping point for circularity, shifting circular materials from early-stage innovation to mainstream reality.”

The plant will exponentially increase the company’s capabilities with the ability to produce the equivalent of hundreds of thousands of garments a year, according to Riley.

Wider horizons

The Jerrabomberra plant also expands Samsara Eco’s enzyme production facilities, enabling the startup to further develop its proprietary platform for enzyme discovery and development to create new recycling solutions for a wider variety of plastics.

The materials made there, Riley said, are expected to feature in upcoming product lines for global brands like Lululemon, which the company recently partnered with.

In June, Lululemon and Samsara Eco entered into a 10-year offtake agreement that could one day see Samsara Eco’s materials support around 20% of Lululemon’s overall fibres portfolio.

Last year, the companies brought to market the world’s first enzymatically recycled nylon 6,6 sample top and a limited edition recycled polyester anorak.

The facility will also host research to find new recycling solutions for plastics and synthetic fibres. Samsara Eco recently partnered with The LYCRA Company, for example, to develop recycling pathways for spandex.

The company also recently teamed up with Deakin Research to expand its work into how additives like dyes and finishes in textiles impact recyclability.

Circling back

“Our new facility will help brands deliver circularity,” said Riley. “This isn't just about building a plant. It's about building a circular future where materials don’t have an end-of-life.

“Circularity won’t happen overnight. But breakthroughs like this, combined with forward-looking policy and brands prioritising circular models, bring us a whole lot closer.”

Samsara Eco also said it was planning to open a 20,000-tonne commercial facility in Asia in 2028 to recycle nylon 6,6 in partnership with engineering firm KBR. This will be the first of several international plants to apply its technology at industrial scale, according to the company.

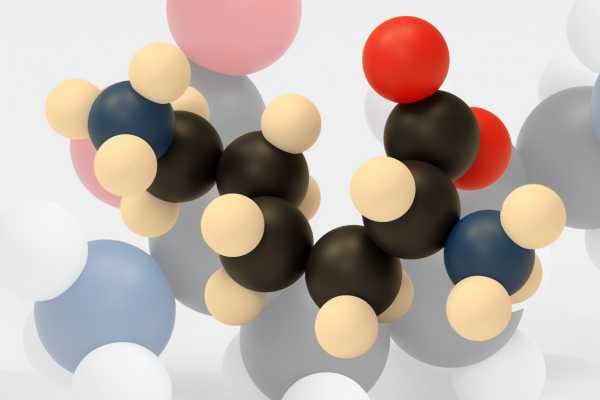

Samsara Eco’s enzymatic technology, developed in collaboration with the Australian National University, has been designed to break down complex plastics that are usually destined for landfill. Unlike traditional mechanical recycling, which often degrades the quality of materials, the startup’s enzymes dismantle plastics chemically at the molecular level in a depolymerisation process that converts plastics back into their original building blocks, known as monomers. The result is a raw material that can be reused without loss of performance or quality in the production of new plastics, allowing for an infinite and cost-efficient recycling process.

Related stories